Everything About Stretch Wrap Machine Repair Service: Important Tips for Preserving Your Devices

Preserving a stretch Wrap Machine is necessary for guaranteeing its performance and long life. Regular evaluations and attending to typical problems can stop expensive downtime. Comprehending the Machine's elements and applying regular upkeep methods are crucial actions. Numerous operators overlook the subtleties of troubleshooting and correct training. What are the very best practices for keeping your tools in leading form? Checking out these vital aspects can lead to even more trustworthy procedures and fewer unexpected failings.

Comprehending the Components of Stretch Wrap Machines

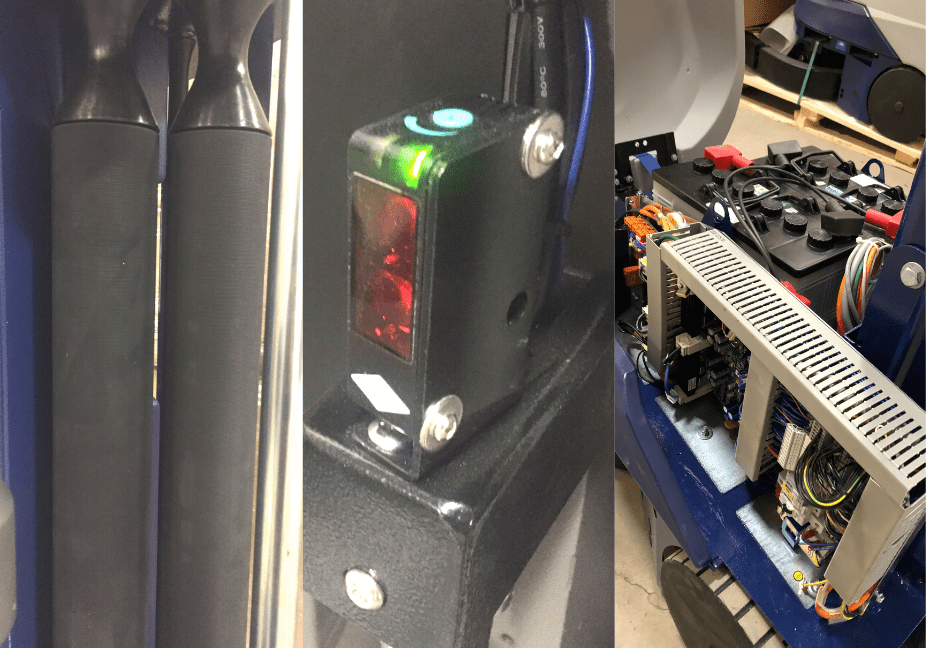

Stretch Wrap machines are crucial devices in packaging procedures, created to safeguard products on pallets for storage space and transport. Understanding their parts is basic for efficient maintenance and procedure. Crucial element consist of the movie carriage, which gives the stretch movie, and the turntable or arm that rotates the tons for also covering. The control board enables operators to change settings such as stress and speed, guaranteeing excellent wrapping problems. Furthermore, the power supply is essential for the Machine's procedure, while the frame gives architectural honesty. Sensors are additionally integrated to identify tons dimension and adjust covering appropriately. Each component plays a considerable role in the general performance of the Machine. Regular knowledge with these parts can help drivers in troubleshooting and regular maintenance, protecting against downtime and making sure continual productivity in the product packaging procedure. Understanding these parts is the primary step to making certain durability and integrity in stretch Wrap equipments.

Usual Problems and Their Solutions

In any kind of product packaging operation, problems with stretch Wrap equipments can arise in spite of a strong understanding of their parts. One common problem is inconsistent covering stress, which can bring about under- or over-wrapped loads. Adjusting the tension setups or inspecting the film feed can often rectify this problem. One more regular worry is film tearing, normally triggered by inadequate quality material or incorrect handling. Switching to higher-quality film and making sure correct loading techniques can assist avoid this. Furthermore, Machine jams might happen as a result of particles or imbalance. Frequently looking for blockages and making sure that elements are properly lined up can reduce this threat. Ultimately, electric failures can disrupt operations; checking links and changing malfunctioning components is necessary. Resolving these typical concerns immediately can improve Machine performance and lengthen devices life-span, inevitably making sure efficient product packaging procedures.

Regular Upkeep Practices

Regular maintenance practices are necessary for the durability and effectiveness of stretch Wrap makers. A daily evaluation checklist, a distinct lubrication routine, and clear component substitute standards are vital elements of this upkeep routine. Carrying out these practices can assist prevent unforeseen breakdowns and guarantee smooth procedure.

Daily Inspection Checklist

Normal evaluations of the stretch Wrap Machine are essential for making sure peak efficiency and long life. A daily assessment list should include vital components to keep track of. Initially, drivers must inspect the film tension and positioning to protect against uneven wrapping. Next, the Machine's electrical links must be checked out for wear or damage, as faulty electrical wiring can bring about functional failures - stretch wrap machine repair near me. Furthermore, the belts and rollers must be inspected for any indications of deterioration, ensuring smooth activity. Lastly, verify that safety and security guards are in place and working properly. By sticking to this day-to-day list, drivers can identify potential concerns early, minimizing downtime and extending the life of the stretch Wrap Machine. Constant assessments eventually add to efficient and dependable procedures

Lubrication Set Up Significance

Although usually ignored, a well-structured lubrication timetable plays a critical role in the maintenance of stretch Wrap makers. Consistently applying the appropriate lubes to essential elements decreases rubbing, lessens wear, and enhances total performance. This proactive strategy not only expands the life-span of the devices yet likewise guarantees regular efficiency, minimizing the likelihood of unanticipated malfunctions. Operators should abide by the manufacturer's referrals pertaining to lubrication intervals and kinds of lubes to make use of. Keeping an eye on lubrication levels and observing any type of adjustments in Machine operation can provide beneficial insights right into possible issues. Inevitably, a diligent lubrication routine is essential for preserving efficiency and integrity in stretch Wrap makers, contributing significantly to functional productivity and cost-effectiveness.

Part Replacement Standards

Troubleshooting Tips for Quick Repair Works

When experiencing problems with a stretch Wrap Machine, swift troubleshooting can significantly decrease downtime and enhance efficiency. Operators needs to initially consult the Machine's guidebook for certain error codes or indications. An usual issue is incorrect tension; readjusting the tension settings can usually solve inconsistent covering. If the movie is not feeding correctly, looking for blockages or making sure the movie is filled correctly is essential.Another frequent issue is the Machine stalling. In this instance, checking the electrical links and fuses might reveal concerns. Consistently lubricating relocating parts can protect against mechanical failings, while guaranteeing that all parts are straightened will certainly improve her explanation performance. In addition, checking the Machine for unusual sounds can provide early cautions of prospective breakdowns. Executing these repairing steps can cause fast repair work, decreasing disruptions in operations and keeping reliable workflow.

When to Look For Specialist Help

When to look for professional assistance for a stretch Wrap Machine is vital for keeping functional efficiency, recognizing. Indications such as uncommon sounds or resonances, frequent film breakage, and inconsistent Wrap tension can suggest underlying problems that need skilled focus. Addressing these problems quickly can stop additional damages and ensure the Machine runs efficiently.

Uncommon Sounds or Resonances

Uncommon sounds or vibrations from a stretch Wrap Machine can indicate underlying issues that may compromise its performance. These anomalies frequently suggest misalignment, worn components, or insufficient lubrication, every one of which can bring about more considerable troubles if left unaddressed. Operators must keep an eye on the Machine carefully for any changes in audio or resonance patterns, as this can give vital insight into its problem. If the sounds are consistent or the resonances are excessive, it is advisable to look for specialist assistance. Neglecting these warning signs might lead to expensive repairs and downtime. Normal assessment and maintenance can reduce risks, but when unsure, seeking advice from a professional guarantees the Machine runs successfully and safely.

Frequent Movie Breakage

Frequent movie damage in a stretch Wrap Machine can signal underlying concerns that require prompt interest. Operators needs to first examine the movie quality, guaranteeing it meets the Machine's specifications. Used or incorrectly mounted movie rollers might likewise add to the issue, bring about boosted tension and film stress. Furthermore, imbalance of the Machine elements can aggravate breakage, suggesting the need for adjustment or replacement of parts. If these basic checks do not solve the issue, it may be time to get in touch with an expert service technician. stretch wrap machine repair near me. Specialist intervention can identify click to read a lot more intricate problems, such as motor malfunctions or software issues, making sure the Machine runs efficiently and efficiently. Prompt specialist help can avoid more damages and expensive fixings

Irregular Wrap Stress

Irregular Wrap stress can bring about improper load stability and increased material waste, making it a considerable worry for stretch Wrap Machine drivers. This problem commonly emerges from tools breakdown, such as damaged elements or incorrect calibration. Operators must keep an eye on stress carefully, as rising and falling degrees can jeopardize the stability of wrapped loads, resulting in damage during transport or storage space. It may indicate much deeper mechanical issues if adjustments to the Machine settings do not resolve the concern. Looking for expert help is recommended when there are persistent incongruities, as seasoned professionals can identify and repair underlying concerns that may not be immediately noticeable. Prompt intervention can not just bring back optimal performance yet likewise extend the life of the stretch Wrap Machine.

Ideal Practices for Avoiding Equipment Failings

While normal maintenance is essential for making certain the durability of stretch Wrap devices, applying finest practices for stopping equipment failings can greatly boost their dependability. Initially, operators need to adhere to a rigorous schedule for regular inspections, concentrating on key elements such as belts, equipments, and motors. Keeping an eye on performance metrics, including Wrap tension and rate, can help determine possible issues before they escalate.Additionally, making sure that the Machine is made use of within its specified ability can reduce unnecessary stress and anxiety on components. Training staff on proper operation methods is crucial, as inappropriate usage can bring about premature wear or damage.Regularly cleansing the Machine to get rid of particles and dust can likewise enhance performance. Lastly, keeping a well-documented upkeep log enables far better monitoring of repairs and can aid in recognizing reoccuring problems. By adhering to these ideal practices, business can substantially decrease the risk of unexpected equipment failings.

Regularly Asked Concerns

Exactly how Commonly Should I Change Stretch Wrap Film?

The frequency of stretch Wrap movie replacement relies on use, ecological elements, and film top quality. Commonly, organizations examine film integrity routinely, changing it when indicators of wear or damages become evident to assure peak efficiency.

Can I Use Non-Standard Movie With My Stretch Wrap Machine?

Utilizing non-standard film with a stretch Wrap Machine might result in compatibility issues, influencing efficiency and potentially causing damages (stretch wrap machine repair near me). It is recommended to speak with the Machine's requirements and maker guidelines prior to attempting to use alternate films

What Are the Indicators of Use in Stretch Wrap Machine Components?

Indicators of wear in stretch Wrap Machine components consist of unusual sounds, inconsistent covering tension, noticeable damage to components, overheating, and boosted downtime. Regular evaluations and upkeep can assist recognize these issues prior to they rise into significant issues.

Are There Certain Cleansing Products Recommended for Upkeep?

The question of recommended cleaning products for maintenance usually occurs. Specialized degreasers and non-corrosive options are commonly recommended, guaranteeing effective cleaning without damaging delicate parts, consequently extending the tools's lifespan and preserving perfect efficiency.

Just How Does Humidity Impact Stretch Wrap Efficiency?

Moisture considerably influences stretch Wrap performance, influencing its adhesion and tension. High humidity can cause lowered cling properties, while low humidity may trigger brittleness, eventually jeopardizing the honesty and performance of the wrapped products. In any packaging operation, issues with stretch Wrap makers can develop regardless of a strong understanding of their components. Regular film damage in a stretch Wrap Machine can indicate underlying problems that need instant focus. Irregular Wrap stress can lead to incorrect tons stability and boosted material waste, making it a considerable worry for stretch Wrap Machine drivers. Using non-standard movie with a stretch Wrap Machine might lead to compatibility concerns, influencing efficiency and possibly triggering damage. Indications of wear in stretch Wrap Machine elements include unusual noises, irregular covering stress, visible damage to components, overheating, and raised downtime.